KBK light crane system

-

Elastic suspension system

- KBK's elastic suspension system (such as spherical hinge design) can significantly reduce vibration and impact during operation, avoid damage to the structure caused by top bending moment and horizontal force, and improve overall stability and safety.

-

Higher rigidity

- The cold-rolled profile and multi-point suspension structure are used, and the modular design enhances the rigidity of the system, disperses the load pressure, and ensures the stability of the structure when heavy objects are hoisted. It supports more efficient heavy-load operations (such as loads above 1 ton) while reducing the loss of accuracy caused by structural deformation.

-

More cost-effective

- Compared with traditional cranes, the KBK system is low-cost, easy to install and low-maintenance. Its standardized modules allow for quick assembly, and the tracks and components can be flexibly expanded, resulting in lower costs for later transformation, saving labor and maintenance costs in long-term use, and significant comprehensive cost-effectiveness.

-

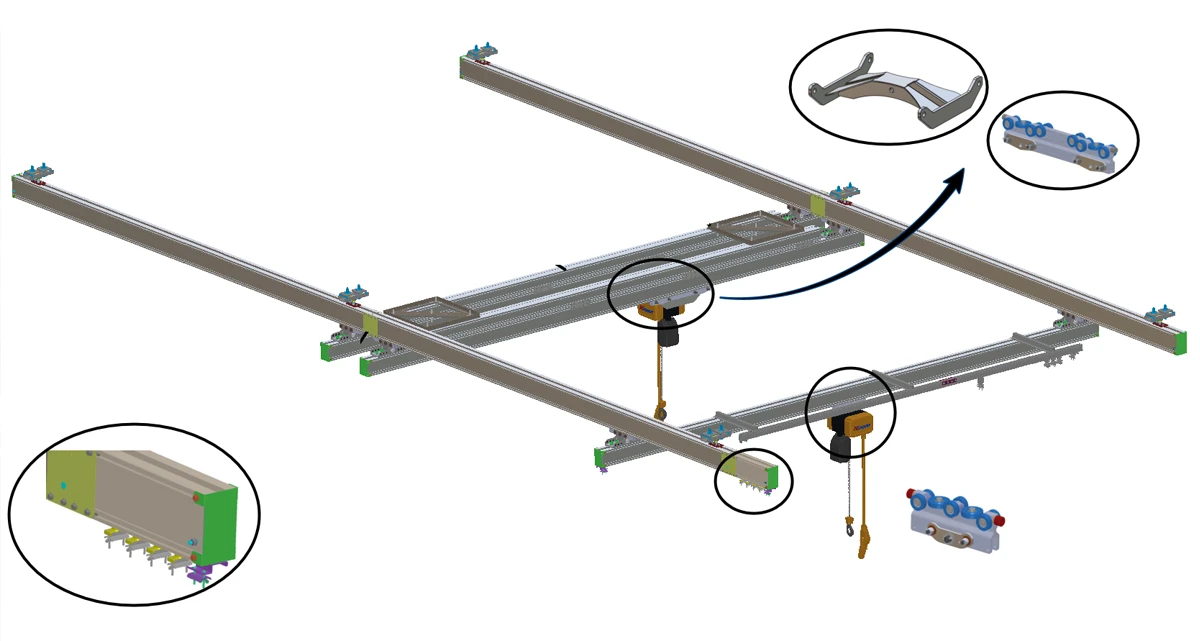

Track system can be expanded and fully automated

- KBK tracks can be freely combined into straight, curved or circular paths, support horizontal/vertical expansion, and can integrate electric drive trolleys, remote control or automation control technology (such as PLC system).

-

Stable operation

- High-quality steel and advanced manufacturing technology are used to ensure the sturdy structure of the crane. The operating mechanism is equipped with a high-precision drive device and a reliable braking system. The operation process is smooth, with low vibration and noise, which can effectively ensure the safety and stability of the lifting process and reduce the risk of damage to the cargo.

-

Easy installation

- The KBK system consists of prefabricated standard modules, which are easy to install on site, shorten the cycle, reduce the difficulty, and reduce the dependence on construction conditions.

-

Flexible lifting

- KBK light crane trolley is light in operation and can be positioned quickly and accurately. It can flexibly adapt to different shapes, weights and lifting requirements to meet diverse production operation scenarios.

-

Cost-effective

- KBK light cranes have low procurement costs, easy installation and maintenance, and high lifting efficiency. They can significantly reduce enterprise costs and improve economic benefits in the long run.

-

Efficient use of space

- The KBK system has a compact structure, and the track can be installed on the roof or wall, saving ground space and improving plant utilization. It is suitable for places with limited space but frequent lifting.

-

Flexibility and adaptability

- KBK cranes can be freely combined and adjusted to adapt to different production environments and needs. Its tracks can be customized into single-beam, double-beam, telescopic beam and other structures, and can be used in conjunction with other lifting equipment (such as tower cranes and bridge cranes). The tracks can be installed in a variety of ways (ground, wall, ceiling), and can be combined into straight, curved, circular and other paths, suitable for new plants or renovation of old systems.

-

Efficiency

- Electric drive technology enables fast and accurate material handling, significantly shortening production cycles. The electric hoist and trolley design improves operating speed and automation, reducing manual operation time.

-

Security and Reliability

- The use of high-strength materials and safety devices (such as limit switches and overload protection) combined with high-quality production of modular standard components ensures structural stability and operational safety. Suspension systems (such as ball hinges) can avoid top bending moments and horizontal forces, reducing the risk of accidents.

-

Space saving and easy installation

- The compact design and height-adjustable suspension save space, and the supporting structure (such as columns and beams) reduces the footprint. Modular components can be quickly assembled by bolts, without complex construction, and are easy to flexibly adjust the layout.

-

Economical and low maintenance cost

- Compared with traditional lifting equipment, KBK system has lower cost, simpler installation and maintenance, and can reduce energy consumption and labor costs in long-term use. Cold-rolled profiles and standardized modules reduce the cost of later expansion or transformation.

-

Wide applicability

- It is suitable for many industries such as machinery manufacturing, automobiles, electronics, logistics, etc., especially for production lines with dense equipment and short-distance high-frequency lifting. The lifting range is 0.125t~2t, and it supports manual, semi-automatic or fully automatic operation.

010203040506070809101112

010203040506070809101112

-

01

Hanger

-

Wide range of applications

Safe connection to various superstructures

Millimeter-precise centering through rail height adjustment

Low maintenance requirements

-

02

Double beam hoist carrier

-

Wide range of applications

Safe connection to various superstructures

Millimeter-precise centering through rail height adjustment

Low maintenance requirements

-

03

Platform Car

-

Wide range of applications

Safe connection to various superstructures

Millimeter-precise centering through rail height adjustment

Low maintenance requirements

-

04

Torsion support

-

Wide range of applications

Safe connection to various superstructures

Millimeter-precise centering through rail height adjustment

Low maintenance requirements

-

05

Main beam + reinforcement beam

-

Wide range of applications

Safe connection to various superstructures

Millimeter-precise centering through rail height adjustment

Low maintenance requirements

-

06

Aluminum alloy track

-

Wide range of applications

Safe connection to various superstructures

Millimeter-precise centering through rail height adjustment

Low maintenance requirements

-

07

Track end plate

-

Wide range of applications

Safe connection to various superstructures

Millimeter-precise centering through rail height adjustment

Low maintenance requirements

-

08

Track connection plate

-

Wide range of applications

Safe connection to various superstructures

Millimeter-precise centering through rail height adjustment

Low maintenance requirements

-

09

Main beam hanger + trolley

-

Wide range of applications

Safe connection to various superstructures

Millimeter-precise centering through rail height adjustment

Low maintenance requirements

-

10

Cable trolley fixed cable clamp

-

Wide range of applications

Safe connection to various superstructures

Millimeter-precise centering through rail height adjustment

Low maintenance requirements

-

11

Hoist trolley

-

Wide range of applications

Safe connection to various superstructures

Millimeter-precise centering through rail height adjustment

Low maintenance requirements

-

12

Suspension track

-

Wide range of applications

Safe connection to various superstructures

Millimeter-precise centering through rail height adjustment

Low maintenance requirements

- Is the KBK modular crane suitable for our production environment?

- KBK modular cranes are suitable for a variety of production environments, including workshops, warehouses, assembly lines, etc. Its modular design allows for flexible adjustment of span, height and load capacity according to demand. The on-site space dimensions (such as height, span), ground load bearing (generally ≥500kg/m²) and lifting requirements (such as maximum load, operating frequency) need to be provided, and the supplier will customize the solution according to the needs.

- What is the load-bearing capacity of the equipment? Can it meet our cargo needs?

- The single-point lifting weight of KBK modular cranes is usually between 125kg and 2000kg, depending on the model and track configuration. For example, the standard KBK II monorail crane has a load capacity of 125kg-2000kg, while the KBK flexible beam system can carry higher weights. The type of goods (such as parts, molds) and the weight of each piece must be provided, and the supplier will recommend an appropriate model.

- How long does the installation take? Are there any special requirements for the site?

- The installation period is usually 1-3 days, depending on the size and complexity of the crane. It is necessary to ensure that the ground of the installation area is flat (horizontal error ≤ 3mm/m), the roof or supporting structure has sufficient load-bearing capacity (generally ≥500kg/m²), and a power interface (220V/380V) is reserved. We will provide on-site inspection and installation guidance.

- Is the operation complex? Does it require specialized training?

- KBK modular cranes are easy to operate and support manual push-pull, electric hoist or remote control operation. The supplier will provide free basic training (1-2 days) covering equipment operation, daily maintenance and safety regulations to ensure that employees can quickly get started.

- How fast is the after-sales response? How long does it take to resolve the problem?

-

Regular suppliers promise:

- Remote support: respond within 2 hours, provide guidance to troubleshoot simple faults.

- On-site service: arrive within 24 hours (within the province)/48 hours (across provinces), 90% of faults can be resolved within 4 hours.